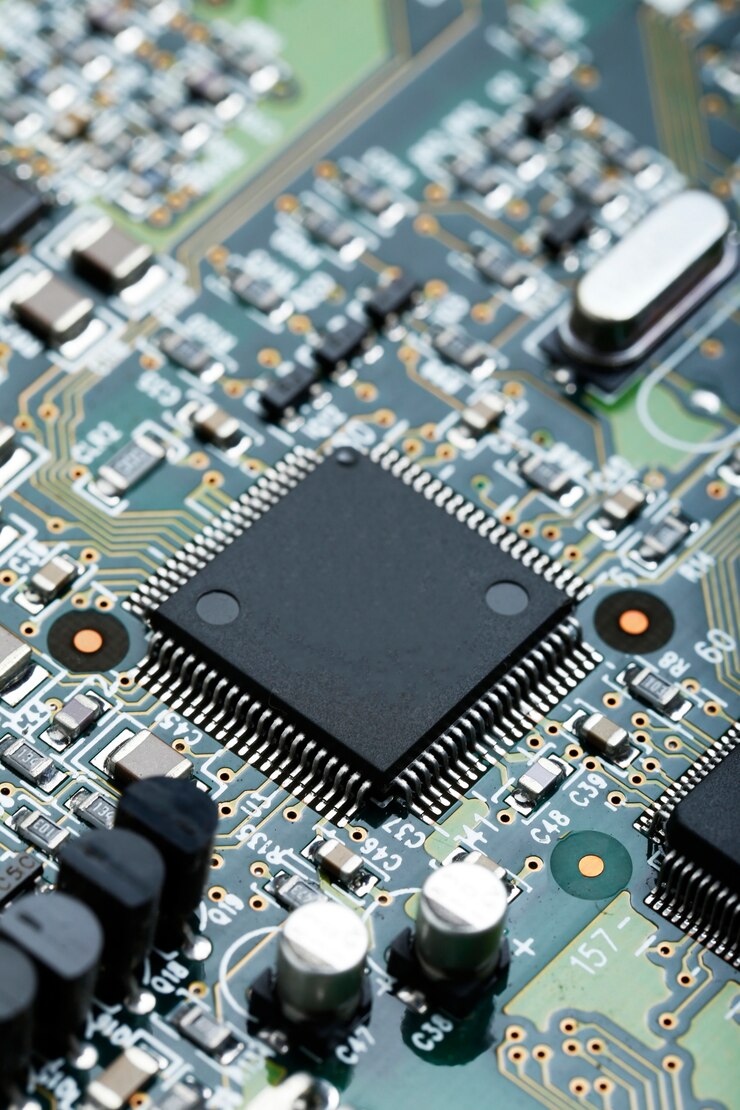

Manufacturing Capabilities

Mechmodule Technology provides comprehensive manufacturing services to meet our clients’ diverse needs. Our advanced facility is equipped with cutting-edge machinery for precision machining, metal fabrication, and custom tooling, all to the highest standards.

We specialize in high-tolerance components and complex assemblies, ensuring top accuracy and consistency.

Our strict quality control processes ensure every product meets exact specifications and industry standards.

With a focus on innovation and efficiency, our advanced capabilities deliver exceptional quality and reliability in every project.

5 Axis CNC Milling

High Speed CNC Machining for Complex and Simple Components

Our advanced high speed machining capabilities allow us to handle a wide range of precision drill & tap operations, ensuring both simple and complex threaded holes are created with accuracy. Utilizing state-of-the-art tapping equipment, we can efficiently process materials such as steel, aluminum, and specialty alloys. Whether working with shallow or deep tapping tasks, our machines are optimized to deliver reliable, high-quality in small and large production runs.

From fine-pitch threads to deep-tap holes, we guarantee outstanding performance with tight tolerances and high-quality finishes, regardless of the complexity of the component. Our solutions cater to industries requiring precision and efficiency, providing consistent, cost-effective tapping services that enhance production processes.

Precision: Accuracy up to 0.005mm.

Capacity: X-axis: 700mm | Y-axis: 400mm | Z-axis: 330mm.

Material Compatibility:

Metals: Alloy Steel, Stainless Steel (300 & 400 Series), Carbon Steel, Aluminum, Titanium, 17-4PH, Invar®, Tool Steel, Copper, Beryllium Copper, Brass, Cast Iron, and more.

Plastics: ABS, Nylon, PEEK, Polycarbonate, Acrylic, Vespel®, Delrin®, UHMW Polyethylene, Torlon®, Celazole®, Ultem®, and more.

Count on us for precision drill & tap solutions that meet the highest industry standards, improving your production efficiency with exceptional, reliable results.

VBX-650

5 Axis Simultaneous CNC Machine

X-850mm Y-4610mm Z-510mm

FANUC ROBODRILL

Compact Machine Centre

Size in MM

X-500mm Y-400mm Z-400mm 10 Units

X-700mm Y-400mm Z-400mm 3 Units

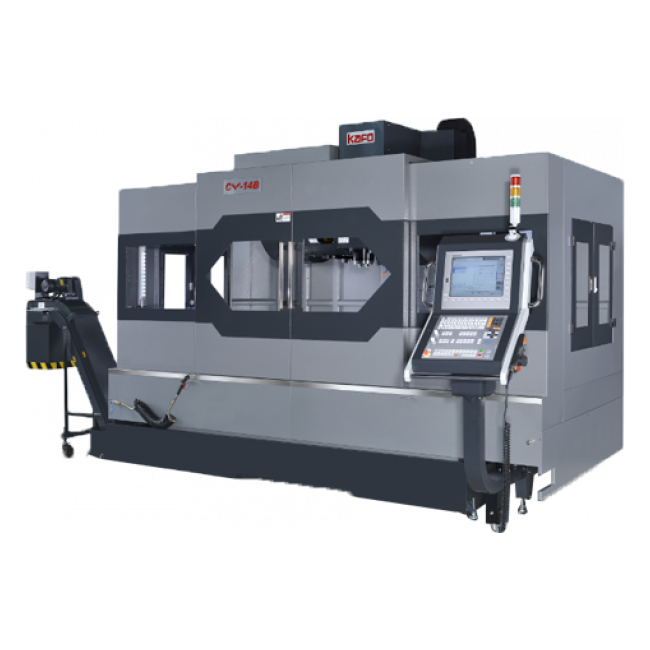

CNC Milling

Precision in Every Detail – From Simple to Complex Components

At Mechmodule, our cutting-edge CNC milling services utilize top-tier 5-axis machines from industry-leading manufacturers. With versatile milling capabilities, we efficiently and precisely produce both intricate and straightforward components, fully customized to your specific requirements.

Our facility is equipped to handle projects of varying sizes and complexities, ensuring precision and cost-efficiency throughout the entire process.

Precision: Accuracy of up to 0.005mm.

Capacity: X-axis: 2600mm | Y-axis: 500mm | Z-axis: 800mm.

Material Compatibility:

Metals: Alloy Steel, Stainless Steel (300 & 400 Series), Carbon Steel, Aluminum, Titanium, 17-4PH, Invar®, Tool Steel, Copper, Beryllium Copper, Brass, Cast Iron, and more.

Plastics: ABS, Nylon, PEEK, Polycarbonate, Acrylic, Vespel®, Delrin®, UHMW Polyethylene, Torlon®, Celazole®, Ultem®, and more.

Experience the perfect balance of precision, versatility, and cost-effectiveness for all your milling needs.

KAFO CV-7A

Vertical Machining Center

X-1600mm Y-700mm Z-700mm

DAHLIH

Vertical Machining Center

X-850mm Y-550mm Z-550mm 1 Unit

X-1200mm Y-600mm Z-600mm 1 Unit

CHEVALIER

Vertical Machining Center

X-1020mm Y-520mm Z-550mm 2 Units

AWEA

Vertical Machining Center

X-800mm Y-500mm Z-500mm 1 Unit

CNC Turning

High-Precision Lathe Machining Services

TAKISAWA NEX-108

Precision Lathe Machine

Chuck 8inch

X-180mm Z-530mm 3 Units

Our precision lathe machining services are designed to meet the diverse needs of various components. With advanced machinery, we excel in producing small to medium-sized parts with exceptionally tight tolerances.

Ideal for machining cylindrical parts, shafts, and complex geometries, we serve industries such as automotive, aerospace, and electronics. With multiple units in operation, we offer scalable production while maintaining consistent quality and timely delivery.

Whether it’s for prototyping or high-volume production, our lathe machining services deliver efficiency, accuracy, and reliability to meet even the most demanding project requirements..

Precision: Accuracy up to 0.005mm.

Capacity: X-axis: 180mm | Z-axis: 530mm.

Material Compatibility:

Metals: Alloy Steel, Stainless Steel (300 & 400 Series), Carbon Steel, Aluminum, Titanium, 17-4PH, Invar®, Tool Steel, Copper, Beryllium Copper, Brass, Cast Iron, and more.

Plastics: ABS, Nylon, PEEK, Polycarbonate, Acrylic, Vespel®, Delrin®, UHMW Polyethylene, Torlon®, Celazole®, Ultem®, and more.

Let us provide the precision and efficiency your project demands.

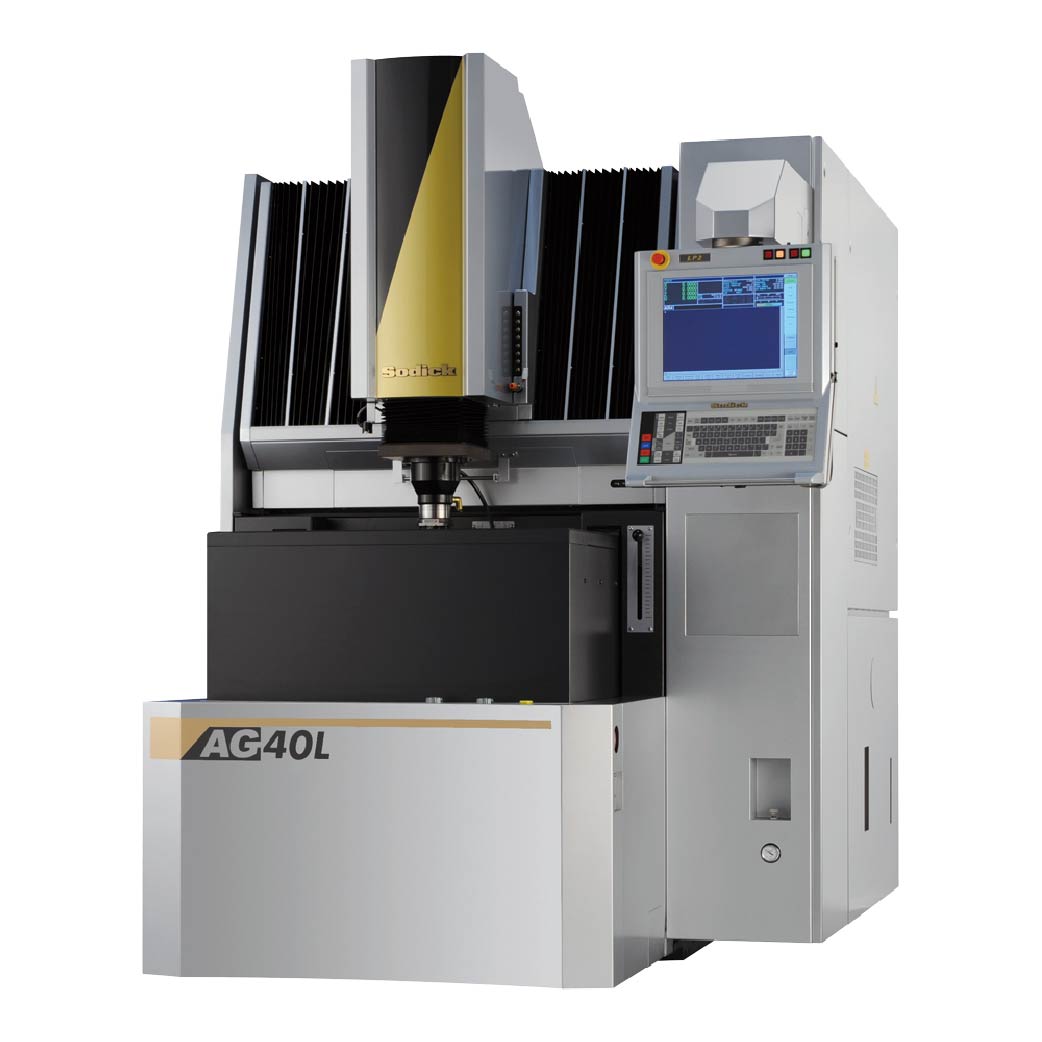

Die Sinking EDM

Unrivaled Precision with Die Sinking EDM Technology

SODICK AG40L

Die Sinking EDM Machine

X-400mm Y-300mm Z-270mm 3 Units

Our advanced EDM technology, including die sinking, excels at machining hard-to-machine materials with exceptional precision. Die sinking EDM enables us to create deep cavities and complex shapes with intricate details, making it perfect for molds and highly detailed component designs. This process provides unparalleled accuracy, especially in areas where traditional machining techniques fall short, ensuring the production of complex geometries without sacrificing quality.

With state-of-the-art EDM units, we specialize in precision manufacturing for deep cavities, undercuts, and intricate features, catering to industries like tooling and mold-making, where the highest level of precision is critical.

Precision: Accuracy up to 0.003mm.

Capacity: X-axis: 400mm | Y-axis: 300mm | Z-axis: 270mm.

Material Compatibility:

Alloy Steel, Stainless Steel (300 & 400 Series), Carbon Steel, Aluminum, Titanium, 17-4PH, Invar®, Tool Steel, Copper, Beryllium Copper, Brass, and more.

Achieve exceptional results with our precision EDM technology for your most complex and detailed projects.

WireCut EDM

High-Precision Wirecut EDM Solutions for Complex Geometries

SODICK Wire Cut AG400L

WEDM Machine

X-400mm Y-300mm Z-250mm 4 Units

Our Wirecut EDM services deliver exceptional accuracy and precision for even the most intricate designs. Using a thin, electrically charged wire, this non-contact cutting process allows us to machine conductive materials with clean, burr-free edges, ensuring exact tolerances without distorting the material.

Wirecut EDM is ideal for creating complex geometries, internal contours, and fine details in materials such as tool steel, titanium, aluminum, and other hard-to-machine alloys. Whether you require intricate parts or larger components, our Wirecut EDM technology ensures consistent, reliable results across all production scales.

Precision: Accuracy up to 0.003mm.

Capacity: X-axis: 400mm | Y-axis: 300mm | Z-axis: 250mm.

Material Compatibility:

Alloy Steel, Stainless Steel (300 & 400 Series), Carbon Steel, Aluminum, Titanium, 17-4PH, Invar®, Tool Steel, Copper, Beryllium Copper, Brass, and more.

Experience high-precision wire EDM machining tailored for your most complex and demanding applications

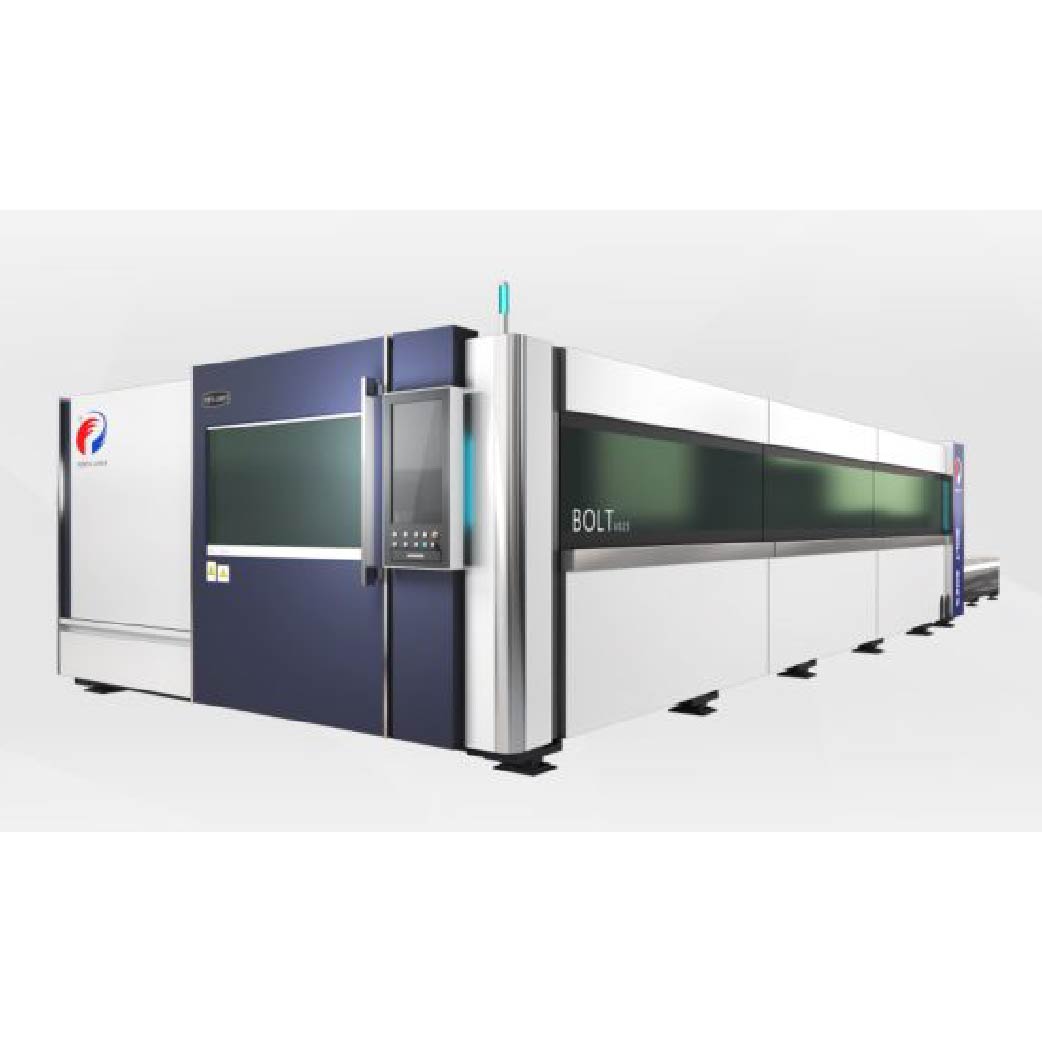

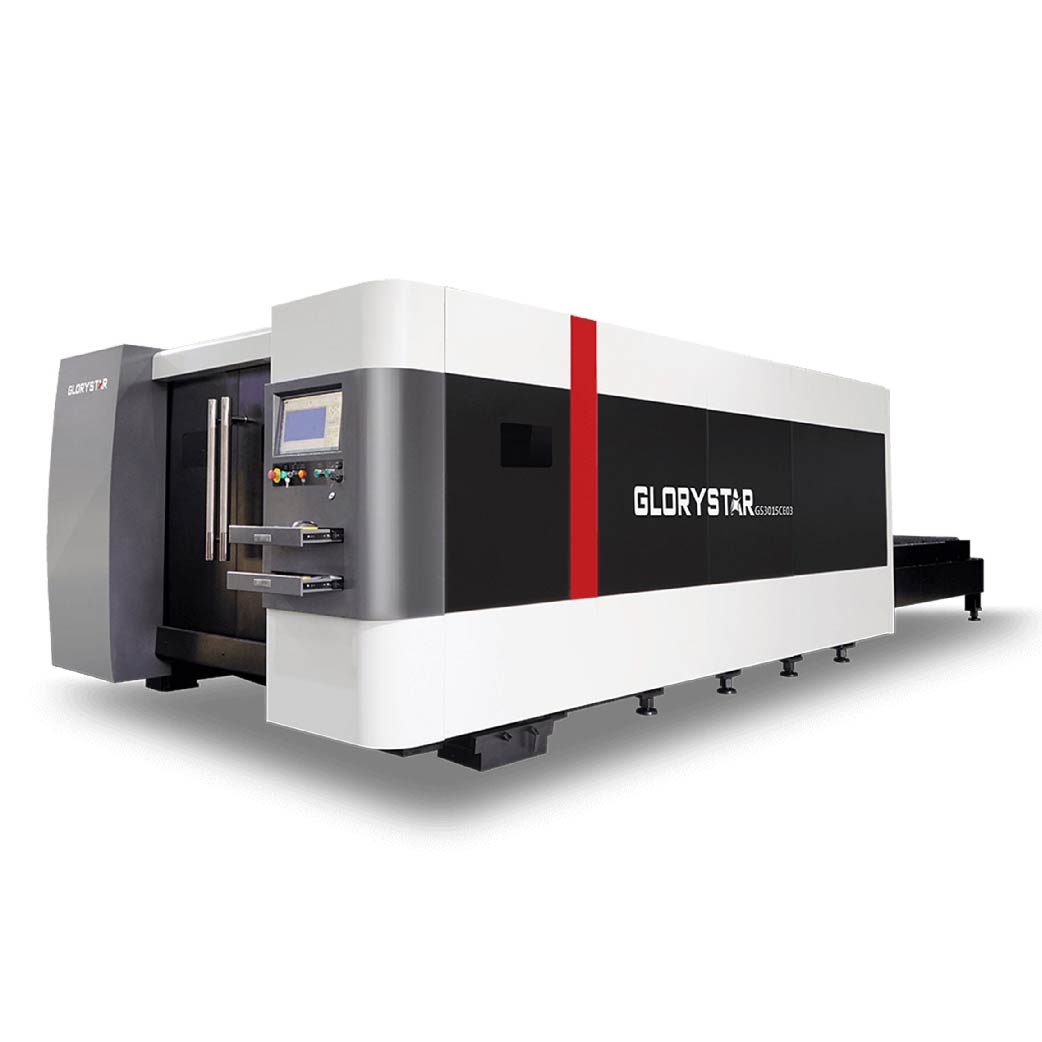

Fiber Laser Cutting

Penta Fiber Laser 12kw

Cutting Thickness up to 40mm

X-6000mm Y2500mm 1 Unit

GLORY STAR Fiber Laser 2kw

Cutting Thickness up to 6mm

X-3000mm Y1500mm 1 Unit

Laser Welding

Advanced Laser Welding Solutions

Nine Laser Welding

1000w 1 Unit

2000w 1 Unit

Our laser welding services deliver precise and clean welds, ensuring minimal heat distortion and high efficiency. Whether working with stainless steel, aluminum, or carbon steel, this process guarantees strong, accurate joins that meet the highest quality standards.

Perfect for high-volume production, our laser welding technology provides exceptional precision, making it suitable for intricate welds and challenging geometries. This makes it ideal for industries such as automotive, aerospace, and electronics, where both accuracy and speed are essential.

Power: 1000W & 2000W.

Capacity: Maximum welding thickness up to 6mm.

Material Compatibility:

Stainless Steel (300 Series), Carbon Steel, Aluminum, Tool Steel, Copper, Brass, and more.

Our advanced laser welding solutions deliver the strength, precision, and efficiency needed for your most complex welding requirements.

Hydraulic Press-Brake

Precision Hydraulic Press-Brake Bending Services

Our hydraulic press-brake offers precision bending capabilities with a powerful capacity of 250 tons, making it ideal for materials such as stainless steel, aluminum, and carbon steel. It handles both simple and complex part formations with exceptional accuracy.

Equipped with advanced controls, our press-brake ensures precise and consistent bends across a variety of sheet sizes. This makes it perfect for producing components like structural parts and metal enclosures that require exact specifications.

Precision: Accuracy up to 0.05mm.

Capacity: Length up to 4100mm, 250 tons.

Material Compatibility:

Stainless Steel (300 Series), Carbon Steel, Aluminum, Tool Steel, Copper, Brass, and more.

Our hydraulic press-brake services provide the precision and reliability you need for high-quality, complex bending applications.

Bystronics

CNC Hydraulic Press Brake 4axis

Length 1000mm x 50Ton 1 Unit

YAWEI

CNC Hydraulic Press Brake up to 7 axis

Length 3100mm x 110Ton 1 Unit

Length 4100mm x 250Ton 1 Unit

Riveting

Precision Riveting Solutions for Reliable Assembly

PEM Insert Machine

1 Unit

We provide high-strength riveting services for joining metals, plastics, and composite materials with precision and reliability. Our advanced riveting machines ensure secure and accurate fastening, making them ideal for industries such as automotive, aerospace, and electronics.

Whether for simple or complex assemblies, our riveting process creates strong, durable joints without the need for heat. Utilizing both automated and CNC-controlled machines, we ensure consistency and precision in every production run, from large-scale batches to smaller projects. Our solutions accommodate various rivet sizes and configurations to meet your specific requirements.

Capacity: 6-ton output Force.

Material Compatibility:

Stainless Steel (300 Series), Carbon Steel, Aluminum, Tool Steel, Copper, Brass, and more.

Our riveting services deliver dependable assembly solutions, ensuring strength and precision for all your fastening needs.

Labelling

100% Batch Traceability

We provide precise laser engraving to ensure full batch traceability, helping prevent counterfeiting and making it easy to track your orders. Our labeling solutions also allow for the inclusion of customized instructions or information on your components for end users.

Laser Labeling

Our advanced laser technology offers a flexible and efficient method for marking metal parts with logos, text, serial numbers, barcodes, or data matrix codes. This process guarantees permanent, high-quality markings that ensure reliable identification and traceability of your components.

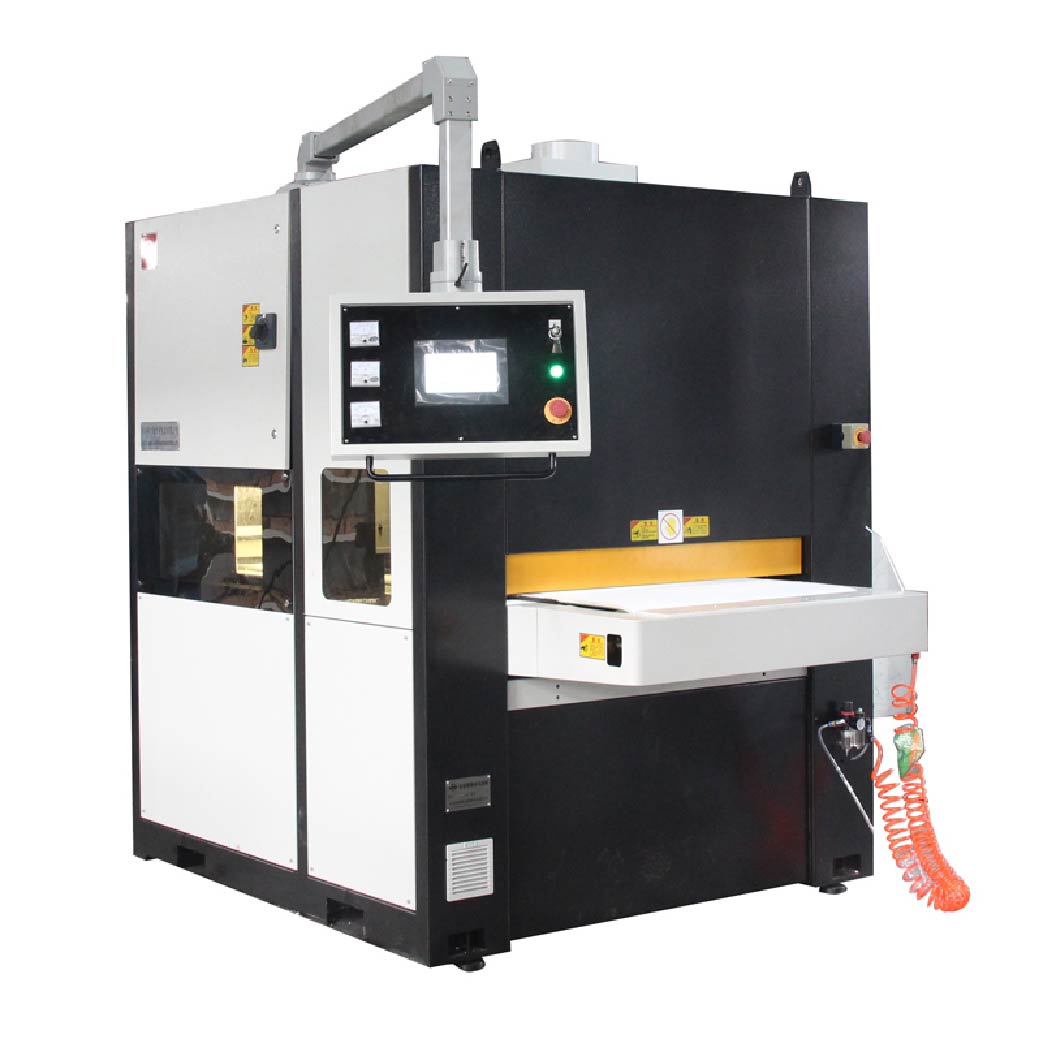

Polishing and Deburring

Precision Deburring and Polishing Solutions

Our deburring and polishing services are designed to enhance the quality and finish of your components. Using advanced hairline machines, we remove sharp edges, burrs, and surface imperfections, ensuring a smooth, refined finish. This process not only improves the aesthetic appeal but also enhances the functionality of the components by reducing friction and improving safety.

Hairline Polishing

The hairline finish we provide is achieved through a meticulous polishing process, creating fine, linear scratches that deliver a sleek, brushed appearance. Ideal for metals such as stainless steel, aluminum, and other alloys, this finish is widely used in industries where both appearance and performance are critical, such as automotive, electronics, and medical applications.

Our hairline machine ensures a consistent and uniform surface finish, resulting in components that meet the highest standards of precision and quality.

Jonsen Hairline Machine

Width 1000mm 1 Unit

Width 630mm 1 Unit

Jonsen Planetary Deburring Machine

Width 1000mm 1 Unit

Assemblies

Ready-to-Use Assemblies

We offer pre-assembled or ready-to-install components, ensuring that your parts are delivered with full functionality and quality. If required, we can perform 100% quality testing on each batch to guarantee perfect results.

Our assembly services include processes such as glue dispensing, pressing, bolting, welding, and more, often in collaboration with trusted external partners. Whatever your specific requirements may be, we are ready to meet your needs and deliver a tailored solution.

Quality Control

At Mechmodule Technology, quality control is central to everything we do. We are committed to delivering products that meet the highest standards of precision, reliability, and performance. Our rigorous quality control processes ensure that every component meets exact specifications, regardless of industry.

Our Commitment to Quality

- Precision at Every Stage: From design to production, we apply strict quality control measures and advanced inspection tools to guarantee precision and meet required tolerances.

- Continuous Improvement: We proactively refine our processes through ongoing monitoring and feedback to achieve higher accuracy and efficiency, ensuring we meet the evolving needs of our clients.

- Compliance with Industry Standards: Our procedures adhere to stringent industry standards, including ISO certifications, ensuring our products meet or exceed expectations in industries such as semiconductor, electronics, automotive, medical devices, and LED lighting.